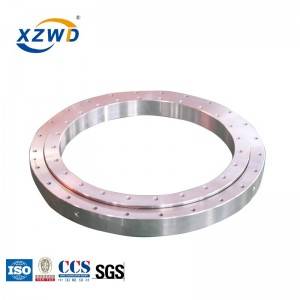

Sreath singilte ceithir puing cuir fios gu ball-bacadh air a bhith a 'toirt buaidh

-

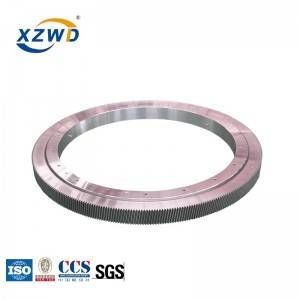

Gèar taobh a-muigh ball sreath aon àite ceithir puing conaltraidh 011 SIne a 'slaodadh

Tha sinn na phrìomh neach-dèanamh de dhiofar chearcall cailidh.

Tha an fhactaraidh againn air a dhol seachad ISO9001: 2015. Leis an aon chàileachd ri brand ainmeil eile.

Ma tha thu ag obair còmhla rinn, faodaidh e do chosgais a shàbhaladh mar thoradh air ar prìs gu math farpaiseach.

-

4 puing àrd-inbhe cuir fios gu ball-tionndaidh Ball le bhith a 'toirt buaidh air roth-uidheaman gaoithe

Tha roth-uidheaman gaoithe mar sheòrsa de lùth uaine is seasmhach. Tha na Bothings Bothings and Bothal Bearsing againn nan pàirtean cudromach de ghineadair roth-uidheam gaoithe, bidh iad ag atharrachadh lùth cineatach a-steach don ghaoth agus ag atharrachadh lùth cineatach a-steach don smachd.

Bidh sinn a 'cleachdadh siostam ròin sònraichte a bheir làn bheathaichean gu tur teann agus bidh sinn cuideachd a' moladh badan aonaichte le siostam lubrication.

-

Xzwd ceithir puing conaltraidh point Point Point Ball a 'giùlan

Bothan fàinne seòlach, no giùlan clàr-tionndaidh, tha beathaichean le stoidhle no sreathan-rolair air a dhèanamh suas de dhà chitheadh co-chòrtaidh aon bhuaithe a dh 'fhaodadh a bhith a' toirt a-steach gèar. Tha an seòrsa seo de bhith a 'neartachadh taic luaidhe agus sgaoileadh cumhachd a' dol a-steach do gach taobh, agus mar as trice thathas mar as trice ag obair gus taic a thoirt do luchdan troimh-slaodaidh airson tagraidhean slaodach agus uidheamachd mòr leithid cladhadairean togail agus crannan togail. Tha an cumhachd sònraichte agus an tiomnadh sònraichte de bhàird chladach a 'toirt orm a bhith a' sìor fhàs luachmhor de ghnìomhachasan, a 'togail togail, togail gnìomhachais, innealan-croise, innealan innealan, agus tagraidhean meidigeach.

-

Na bu shreath stesty-rust nas làidire a 'cadal

Stàilinn nach meirgBearings sòlingtha meirgeach nas làidire agus nas miosa.

Faodar a bhith a 'taghadh Lubairean freagarrach agus seulachadh a chleachdadh aig -60 ℃ ~ 300 ℃.

Faodaidh beannachadh stainc stàilinn gun staoin an aghaidh creimeachd adhbhrachadh le taiseachd agus grunn mheadhanan eile.

-

Clàr-tionndaidh ball singilte Xzwd singilte a 'suirghe

Tha an Ìre saothrachaidh againn a rèir Interst Start Invery JB / T2300-2011, chaidh sinn cuideachd a lorg cuideachd na siostaman riaghlaidh càileachd (QMS) de ISO 9001: 2008 agus GB / T1900001-2008. Bidh sinn a 'snaidheadh sinn fhìn chun R & D de a' ghoil a 'giùlan le mionaideachd àrd, adhbhar agus riatanasan sònraichte.

Bidh sinn a 'cuimseachadh agus smachd air a h-uile mion-fhiosrachadh riochdachaidh, dìreach airson toraidhean math a lìbhrigeadh do luchd-ceannach.

Mar as trice tha stuth nan grèim slewing àrd na stàilinn àrd-structarte, leithid 42crmo, 50mn.

-

Xzwd | Sìona Sìona A 'GABHAIL A-STEACH GU LÀRAICHEAN INVERNIA NÀISEANTA

Dh 'fhaodadh XZW' s sheowing leis a 'chomataidh mhòr a thoirt seachad air cearcall Beathing airson gach neach-pàirtiche againn!

Còmhla airson faighinn seachad air!

Cuir fios thugainn ma tha iarrtas sam bith agad.

Tha an t-sreath toraidh a leanas aig an XZWD a leanas:

1.Tsingle Row ceithir puing fios a chuir gu ball-bacadh air Bearings Bearings.

2.Single Breed croteld rolair smecking Bearings

A 'GABHAIL A' GABHAIL A 'GABHAIL

Robrew Roc Roller 4.three

5.ATIn Earrann a 'giùlan giùlan (Seòrsa Light).

6.mhan Earrann Suinte (Seòrsa fulan)

-

Ball conaltraidh Ceithir ri Ceithir ri Cuairt-tòiseachaidh Cleachdadh le fàinneachan duilich

Bidh sinn a 'cuimseachadh agus smachd air a h-uile mion-fhiosrachadh riochdachaidh, dìreach airson toraidhean math a lìbhrigeadh do luchd-ceannach.

Toradh ri fhaighinn: Ball sreath singilte singilte agus dùbailte, trì rionnach, Crois Rolair agus gun choimeas de ghearan a-staigh agus neo-ghlaool.

Tha clàran-tionndaidh agus fàinneachan slewing air a thabhann anns gach cuid meudan meadaigeach is òirleach leis an comas eadar-aghaidh sreap a chuir an sàs gus an tagradh agad a shallachadh. Dè a tha eadar-dhealaichte bho fhàinneachan slewing bho turntables a 'toirt a-steach fiaclan gèar air an dàrna cuid na fàinneachan a-staigh no a-muigh.

-

Ball sreath Xzwd singilte air a bhith a 'giùlan gèar taobh a-muigh fàinne airson innealan tunail allaidh

Tha an Ìre saothrachaidh againn a rèir Interst Start Invery JB / T2300-2011, chaidh sinn cuideachd a lorg cuideachd na siostaman riaghlaidh càileachd (QMS) de ISO 9001: 2008 agus GB / T1900001-2008. Bidh sinn a 'snaidheadh sinn fhìn chun R & D de a' ghoil a 'giùlan le mionaideachd àrd, adhbhar agus riatanasan sònraichte.

An Wanda Xuzouou a 'cadal le teisteanas toraidh:

1.Tsingle Row ceithir puing fios a chuir gu ball-bacadh air Bearings Bearings.

2.Single Breed croteld rolair smecking Bearings

Ball sreath 3Double 3Double Bearings

Robrew Roc Roller 4.three

5.ATIn Earrann a 'giùlan giùlan (Seòrsa Light).

6.mhan Earrann Suinte (Seòrsa fulan)

Xzwd Tha fhàinneachan slewing air an dealbhadh mar:

■Ceithir Point Bearings

-Tha na fàinneachan searbh sin gun ro-shealladh làidir agus air a dhearbhadh gu fìor dhroch obrachadh gu fìor fheumail; bidh iad a 'tachairt ach beagan de dh' iarraidh air flatness agus feallsanachd an obair a tha faisg air làimh-Tha iad freagarrach airson tagraidhean le riatanasan ìosal airson cruinneas agus mì-chothromachadh an rèiteachadh gèise, uidheamachd cumhachd gaoithe agus innealan togail

Reic ainmeil cruinn cruinneil XZWD ceithir puing fios a chuir gu ball-tionndaidh ball a 'slaodadh fàinne

Toradh ri fhaighinn: Ball sreath singilte singilte agus dùbailte, trì rionnach, Crois Rolair agus gun choimeas de ghearan a-staigh agus neo-ghlaool.

An Wanda Xuzouou a 'cadal le teisteanas toraidh:

1.Tsingle Row ceithir puing fios a chuir gu ball-bacadh air Bearings Bearings.

2.Single Breed croteld rolair smecking Bearings

A 'GABHAIL A' GABHAIL A 'GABHAIL

Robrew Roc Roller 4.three

5.ATIn Earrann a 'giùlan giùlan (Seòrsa Light).

6.mhan Earrann Suinte (Seòrsa fulan)

No Gèar taobh a-muigh Tomhasan (mm) Tomhasan sreap (mm) DIMENTLION PRÌOMH (MM) Dàta gèar Gèar feachd10 ^ 4. Cuideam

kgD d H D1 D2 n Φ dm L n1 D3 d1 H1 h b x M De z N T 1 011.20.200 280 120 60 248 152 12 16 M14 28 2 201 199 50 10 40 0 3 300 98 1.5 2.1 24 2 011.20.224 304 144 60 272 176 12 16 M14 28 2 225 223 50 10 40 0 3 321 105 1.5 2.1 25 3 011.20.250 330 170 60 298 202 18 16 M14 28 2 251 249 50 10 40 0 4 352 86 2.1 2.8 30 4 011.20.280 360 200 60 328 232 18 16 M14 28 2 281 279 50 10 40 0 4 384 94 1.5 2.8 34 5 011.25.315 408 222 70 372 258 20 18 M16 32 2 316 314 60 10 50 0 5 435 85 2.9 4.4 52 6 011.25.355 448 262 70 412 298 20 18 M16 32 2 356 354 60 10 50 0 5 475 93 2.9 4.4 59 7 011.25.400 493 307 70 457 343 20 18 M16 32 2 401 399 60 10 50 0 6 528 86 3.5 5.3 69 8 011.25.450 543 357 70 507 393 20 18 M16 32 2 451 449 60 10 50 0 6 576 94 3.5 5.3 76 9 011.30.500 602 398 80 566 434 20 18 M16 32 4 501 499 498 70 10 60 0.5 5 629 123 3.7 5.2 85 012.30.500 6 628.8 102 4.5 6.2 10 011.30.560 662 458 80 626 494 20 18 M16 32 4 561 559 558 70 10 60 0.5 5 689 135 3.7 5.2 95 012.25 / 30.560 6 688.8 112 4.5 6.2 11 011.30.630 732 528 80 696 564 24 18 M16 32 4 631 629 628 70 10 60 0.5 6 772.8 126 4.5 6.2 110 012.25 / 30.630 8 774.4 94 6 8.3 / 8.2 12 011.30.710 812 608 80 776 644 24 18 M16 32 4 711 709 708 70 10 60 0.5 6 850.8 139 4.5 6.2 120 012.30.710 8 854.4 104 6 8.9 / 8.3 13 011.40.800 922 678 100 878 722 30 22 M20 40 6 801 798 90 10 80 0.5 8 966.4 118 8 11.1 220 012.40.800 10 968 94 10 14.1 / 14 14 011.40.900 1022 778 100 978 822 30 22 M20 40 6 901 898 90 10 80 0.5 8 1062.4 130 8 11.1 240 012.40.900 10 1068 104 10 14 15 011.40.1000 1122 878 100 1078 922 36 22 M20 40 6 1001 998 90 10 80 0.5 10 1188 116 10 14 270 012.30 / 40.1000 12 1185.6 96 12 16.7 16 011.40.1120 1242 998 100 1198 1042 36 22 M20 40 6 1121 1118 90 10 80 0.5 10 1298 127 10 14 300 012.30 / 40.1120 12 1305.6 106 12 16.7 17 011.45.1250 1390 1110 110 1337 1163 40 26 M24 48 5 1252 1248 100 10 90 0.5 12 1449.6 118 13.5 18.8 420 012.35 / 45.1250 14 1453.2 101 15.8 21.9 18 011.45.1400 1540 1260 110 1487 1313 40 26 M24 48 5 1402 1398 100 10 90 0.5 12 1605.6 131 13.5 18.8 480 012.35 / 45.1400 14 1607.2 112 15.5 21.9 19 011.45.1600 1740 1460 110 1687 1513 45 26 M24 48 5 1602 1598 100 10 90 0.5 14 1817.2 127 15.8 21.9 550 012.35 / 45.1600 16 1820.8 111 18.1 25 20 011.45.1800 1940 1660 110 1887 1713 45 26 M24 48 5 1801

18021798 100 10 90 0.5 14 2013.2 141 15.8 21.9 610 012.35 / 45.1800 16 2012.8 123 18.1 25 21 011.40 / 60.2000 2178 1825 144 2110 1891 48 33 M30 60 8 2001

20021998 132 12 120 0.5 16 2268.8 139 24.1 33.3 1100 012.40 / 60.2000 18 2264.4 123 27.1 37.5 22 011.40 / 60.2240 2418 2065 144 2350 2131 48 33 M30 60 8 2241

22422238 132 12 120 0.5 16 2492.8 153 24.1 33.3 1250 012.40 / 60.2240 18 2498.4 136 27.1 37.5 23 011.40 / 60.2500 2678 2325 144 2610 2391 56 33 M30 60 8 2501

25022498 132 12 120 0.5 18 2768.4 151 27.1 37.5 1400 012.40 / 60.2500 20 2776 136 30.1 41.8 24 011.40 / 60.2800 2978 2625 144 2910 2691 56 33 M30 60 8 2802 2798 132 12 120 0.5 18 3074.4 168 27.1 37.5 1600 012.40 / 60.2800 20 3076 151 30.1 41.8 25 011.50 / 75.3150 3376 29222 174 3286 3014 56 45 M42 84 8 3152 3147 162 12 150 0.5 20 3476 171 37.7 52.2 2800 012.50 / 75.3150 22 3471.6 155 41.5 57.4 Nòta:

1. Is e N1 na h-àireamhan de thuill lubricating hols.ail cupa m10 × 1jb / T7940.1 ~ JB / T7940.2.2 Cèitean a bhith ag atharrachadh a rèir tagradh an neach-cleachdaidh.

2. Chan eil n-φcan ag atharrachadh gu toll tapaidh, is e trast-thomhas de tholl tappy m, is e doimhneachd 2m.

3. Is e am feachd fiamheas bainnse anns an fhoirm an fheachd aig an àm as àirde, an fheachd fiamhlachd Mangential ainmichte 1/2 den mhàileid as motha.

4. Tha "k" a 'leantainn leotha fhèin co-èifeachd.

Xzwd Tha fhàinneachan slewing air an dealbhadh mar:

■Ceithir Point Bearings

-Tha na fàinneachan searbh sin gun ro-shealladh làidir agus air a dhearbhadh gu fìor dhroch obrachadh gu fìor fheumail; bidh iad a 'tachairt ach beagan de dh' iarraidh air flatness agus feallsanachd an obair a tha faisg air làimh -

Xzwd àrd astar sreath sreath sreathach singilte Ceithir puing conaltraidh a 'bualadh air Ball a' slaodadh

Faodaidh na daoine sin taic a thoirt do amannan mòra ann an suidheachaidhean nuair a bhios luchd-luchdachadh air falbh bho na h-axis sa mheadhan le buaidh.

Tha clàran-tionndaidh agus fàinneachan slewing air a thabhann anns gach cuid meudan meadaigeach is òirleach leis an comas eadar-aghaidh sreap a chuir an sàs gus an tagradh agad a shallachadh. Dè a tha eadar-dhealaichte bho fhàinneachan slewing bho turntables a 'toirt a-steach fiaclan gèar air an dàrna cuid na fàinneachan a-staigh no a-muigh.

Fòcas agus smachd a h-uile mion-fhiosrachadh riochdachaidh, dìreach airson toraidhean math a lìbhrigeadh do luchd-ceannach.

Mar as trice tha stuth nan grèim slewing àrd na stàilinn àrd-structarte, leithid 42crmo, 50mn.

Is e an stuth gluasadach GCR15 agus tha e air a cheannach bho sholaraichean dachaigheil le càileachd as àirde. -

Xameter Singilte Timame Singilte Timey Ball Polymer Polymer a 'cadal

An t-sreath singilte ceithir puing cuir fios gu ball-bacadh air a bhith a 'giùlanAir a dhèanamh suas de 2 rings suidheachain.it tha feartan compact ann an dealbhadh, agus solas a 'conaltradh ris a' cheann cruinn, Co-dhiù dh 'fhaodadh gum bi an fheachd axial, Feachd Ratial agus Momadh Ratial Feachd agus Ratial Fortan agus Ratial Feachd agus Bontial Fortan agus Ronial Fortan agus Mion Feachd Ratial agus Ratial Fortan agus Mion Feachd Ratial.

Faodar a chleachdadh airson a 'ghiùlain sòchdail, gàirdeanan tàthaidh, crannan, cliùiteach, cladhadairean meadhanach agus innealan innleadaireachd eile. -

Xzwd | slewed proifeasanta le inneal-saothrachaidh tàthaidh airson inneal-fuadain tàthaidh

Tha cleachdadh farsaing de innealan-fuadain gnìomhachais ann am factaraidhean fèin-ghluasadach air èifeachdas cinneasachaidh a leasachadh gu mòr. Is e gàirdean meacanaigeach a th 'anns a' phrìomh dhòigh inneal-fuadain gnìomhachais. Tha an dealbhadh structarail ioma-ìre saor-ìre a 'ceadachadh sùbailteachd fìor àrd aig a' ghearas cùbhraidh. Faodaidh e puingean a lorg gu ceart agus gluasad a rèir slighe shònraichte san fhànais. Tha uidheamachd rothain a 'gheamhraidh meacanaigeach a' cleachdadh siolandair uisgeachaidh rothlach no servo motor gus an gnìomh rothlach a thoirt gu buil tro ghlaodh fàinne caol.

-

Neach-dèanamh proifeasanta a 'sìor fhàs airson suidheachadh tàthaidh

PREITING WELLINGair an dealbhadh gus a 'phàirt a shuidheachadh anns an t-suidheachadh tàthaidh as fheàrr.it tha e na sheòrsa de uidheamachd taic Welding le Labhraiche Taller.